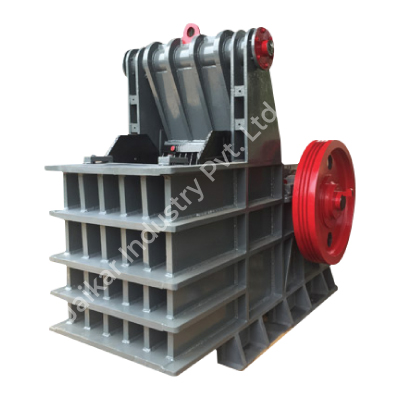

Jaw Crusher Machine Manufacturer Exporters Amritsar are heavy duty machines. They are robustly manufactured. Jaw Crusher Machine Manufacturer Exporters Amritsar consists of a main frame and two plates which move like jaws. Both jaws are adjusted to an intense angle to each other. First jaw is pivoted in such a manner that it moves relatively towards another fixed jaw. The movable jaw plate pivoted at the top on the swing-jaw shaft. In the jaw type of crusher oscillation of pivoted jaw is caused to motion by the action of toggles and pitman, that moves upside and down actuated by the eccentric through the medium of pulleys mounted on the drive shaft

Jaw Crusher Machine Manufacturer Exporters Amritsar is primary used for crushing big lumps of slag. As the material fed into the Jaw Crusher Machine Manufacturer Exporters Amritsar, Heavy duty hardened Jaw Crusher Machine Manufacturer Exporters Amritsar the big lumps of slag in medium size which then goes to the next process.

Depends upon the hardness of Slag (e.g. Induction furnace slag of Arc furnace slag.) Jaw crusher also used by various industries for crushing stone, coal, hard coke, refectory, ferro manganese, iron ore, etc.

In order to make use of the rocks or ores obtained through quarrying/explosion in the Mining and Construction sectors, the materials need to be crushed to reduce them to a smaller size. We call this process SIZE REDUCTION or CRUSHING.

The goals of the size reduction are as follows:

In general, crushing is carried out in three stages, depending on the desired size of the material.

A Jaw Crusher Machine Manufacturer Exporters Amritsar uses compressive force for breaking material. This mechanical pressure is achieved by the crusher's two jaws dies, one of which is stationary and the other is movable. These two vertical manganese jaw dies create a V-shaped cavity called the crushing chamber, where the top of the crushing chamber is larger than the bottom. Jaw Crusher Machine Manufacturer Exporters Amritsars are sized by the top opening of the crushing chamber. For example, a 32 x 54 Jaw Crusher Machine Manufacturer Exporters Amritsar measures 32" from jaw die to jaw die at the top opening or gape opening and 54” across the width of the two jaw dies.

The narrower bottom opening of the crushing chamber is used to size the discharge material. A toggle plate and tension rods hold the pitman tight near the bottom of the moving swing jaw. The toggle plate is designed to perform like a fuse and protect the crusher in the event that an uncrushable material enters the crushing chamber. As a rule, Jaw Crusher Machine Manufacturer Exporters Amritsars have a 6:1 or 8:1 ratio for crushing material. Still using the 32 x 54 Jaw Crusher Machine Manufacturer Exporters Amritsar example, the top size of the feed entering the crushing chamber has to follow the F80 rule that 80% of the top size feed material is smaller than the gape opening. Using the F80 rule with the 32 x 54 Jaw Crusher Machine Manufacturer Exporters Amritsar, the 32” gape opening equals a 26” top sized feed, and with the 6:1 ratio of reduction, the discharge setting would be around 4”.

Since the crushing of the material is not performed in one stroke of the eccentric shaft, massive weighted flywheels are attached to the eccentric shaft and powered by a motor. The flywheels transfer the inertia required to crush the material until it passes the discharge opening.